When you don’t maintain thermostatic mixing valves (TMVs) properly, it can lead to serious issues like scalding injuries and legionella outbreaks. These risks show the importance of regularly checking these vital components in public places.

Thermostatic mixing valves are critical in maintaining safe water temperature by blending hot and cold water. This process ensures that hot and cold water are mixed effectively to prevent scalding. A reliable mixing valve must be addressed in facilities such as hospitals and schools with vulnerable populations.

This article offers a detailed guide on maintaining thermostatic mixing valves. Grasping how they function is key to keeping things safe and compliant. We’ll delve into how these valves operate within hot water systems and why they’re crucial for regulating temperature. Taking care of these valves is essential for everyone’s safety.

Thermostatic Mixing Valves (TMVs) in Public Facilities

A thermostatic mixing valve (TMV) blends hot and cold water to deliver aconsistent and safe water temperature. This prevents scalding and ensures that the heated water remains at a safe level for use. TMVs are integral to any effective water system, ensuring all users’ water supply remains safe.

The importance of thermostatic mixing valves (TMVs) in environments like hospitals, aged care homes, and schools cannot be overstated. Vulnerable populations, including the elderly and children, require protection from sudden temperature changes. Hot water systems equipped with tempering valves provide this security, delivering warm water at a safe temperature.

TMVs are vital in preventing scalding and ensuring compliance with health standards. Regulations often mandate tempering valve systems to maintain consistent water temperatures. Properly functioning TMVs in the water supply are essential for meeting these standards and ensuring facilities adhere to safety and regulatory requirements.

Facilities Requiring TMV Installation

TMVs are key players in water safety across different settings. By mixing hot and cold water, they help prevent scalding, making them indispensable in places like hospitals, aged care facilities, schools, childcare centres, hotels, and gyms. In commercial plumbing, TMVs are often a requirement, ensuring users are kept safe with consistent water temperatures.

TMVs are vital for upholding public health standards in hospitals and aged care facilities. Schools and childcare centres need them to prevent injuries to children. Likewise, hotels and gyms must comply with safety regulations to protect guests, especially when installing new hot water systems.

What Should You Consider?

When selecting plumbing systems, it’s crucial to assess several key factors to ensure they’re both efficient and compliant. These considerations will help tailor solutions to fit specific needs and conditions.

Facility Type and Intended Use

The type of facility—whether residential, commercial, or industrial—determines the specific plumbing requirements. Each type demands different capacities and functionalities to effectively meet its intended use.

Number of Outlets and Flow Rate Requirements

Assessing the number of outlets and the necessary flow rate is crucial. High-demand areas require systems that maintain consistent pressure and deliver adequate water volume without compromising performance.

Temperature Range and Precision Requirements

Some applications require precise temperature control, especially in healthcare and food services. Ensuring the system meets these precise requirements is essential for safety and efficiency.

Compliance with Relevant Standards and Regulations

Adhering to local and national plumbing codes is mandatory. These regulations ensure safety, environmental protection, and quality standards are met, preventing legal issues and potential hazards.

Installation Requirements and Compatibility

New installations must be compatible with existing plumbing infrastructure to avoid costly modifications. Proper assessment can prevent disruptions and ensure smooth integration.

Professional Consultation

Engaging with plumbing professionals is vital for accurate assessment and installation. Experts can provide insights into system capabilities, potential challenges, and cost-effective solutions, ensuring the project meets all necessary standards and functions optimally.

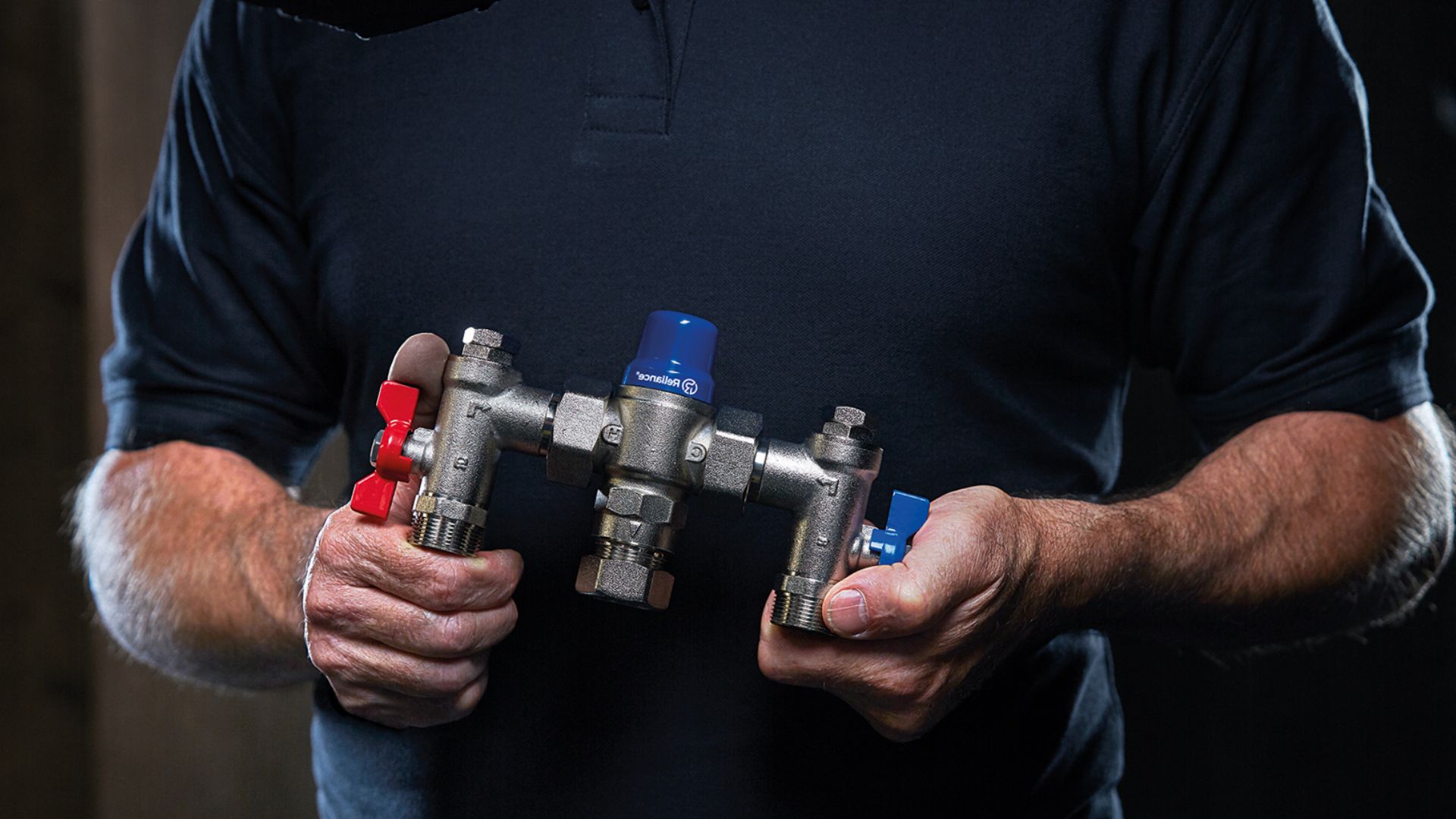

Types of TMVs

Understanding the different types of TMVs helps select the right one for specific applications. Several kinds of TMVs are designed to cater to various needs.

- Pressure-balanced TMVs are reliable in managing sudden pressure changes in the water supply, ensuring consistent temperature.

- TMVs with check valves prevent backflow, safeguarding the water supply from contamination.

- High-performance TMVs are crafted for specialised applications, offering robust solutions to demand environments such as hospitals or extensive public facilities.

Each type of TMV is suitable for specific facilities. Pressure-balanced TMVs are ideal for residential and commercial settings where pressure fluctuations are common. TMVs with check valves are crucial in any facility where water safety is prioritised, ensuring contamination-free supply. High-performance TMVs are best suited for environments requiring rigorous temperature control and reliability, such as healthcare institutions, where any deviation can impact safety and comfort.

Regulations and Compliance for TMVs in Public Facilities

Essential Australian standards like AS/NZS 3500.4:2018andAS/NZS 4032.1:2005provide essential TMV installation and maintenance guidelines.AS/NZS 3500.4:2018 is a comprehensive manual that ensures TMVs function correctly and safely. Meanwhile, AS/NZS 4032.1:2005 focuses on the materials, design, and performance requirements, serving as a quality assurance measure for TMVs.

Keeping up with these guidelines is vital as standards may evolve. Regularly reviewing updates ensures compliance and maintains the safety and performance of the TMVs.

State and Local Regulations

While national guidelines exist, states and territories may have specific requirements, such as testing frequency or temperature limits. For instance, some states mandate annual testing, while others have different intervals.

Engaging with local authorities is essential to ensure compliance with regional variations. It ensures that all specific local requirements are met, avoiding potential discrepancies.

Compliance Violations

Non-compliance with TMV regulations can lead to serious legal repercussions. Facilities may face lawsuits if safety hazards arise due to improper maintenance or installation. Ensuring TMVs are up to standard protects public health and maintains safe operations.

Failure to adhere to regulations can result in hefty fines and legal liabilities. These financial penalties can significantly impact the facility’s budget and reputation. Staying compliant not only avoids these costs but also ensures the safety and trust of users.

Common TMV Problems and Troubleshooting

Addressing common TMV issues promptly is crucial to maintaining efficiency and safety in plumbing systems.

Temperature Fluctuations

Temperature fluctuations can be caused by worn-out elements, mineral build-up, or debris obstructing the valve. Over time, these issues can compromise the valve’s ability to maintain a consistent temperature. Hard water can exacerbate mineral accumulation, leading to erratic performance.

Troubleshooting Tips:

To address temperature issues, start by inspecting and cleaning the valve. Remove any visible debris and check for mineral deposits, using a descaling solution if necessary. Regular maintenance, including checking for worn parts and replacing them, can prevent fluctuations. It’s also essential to ensure the water pressure is within the recommended range for your TMV model.

Leaks and Drips

Damaged seals, worn washers, or improper installation often cause leaks and drips. Over time, seals can degrade, allowing water to escape from the valve. Incorrect installation may cause misalignment, resulting in leaks.

Preventative Measures:

To prevent leaks, ensure proper installation by following manufacturer guidelines. Regularly inspect seals and washers, replacing them when signs of wear appear. Using high-quality components during installation can enhance durability. Regular maintenance checks can help catch potential issues early, keeping the TMV operating efficiently.

Valve Failure

Valve failure can occur due to a lack of maintenance, exposure to extreme temperatures, or corrosive water conditions. Minor issues can escalate without regular inspection, leading to complete valve failure.

Identifying Failure:

Signs of valve failure include inconsistent water temperatures, complete loss of temperature control, or unusual noises. If these symptoms arise, it may indicate internal damage or a malfunctioning thermostat. Regularly testing the valve and monitoring these signs can help identify failure early. If failure is suspected, it’s advisable to consult a professional for assessment and potential replacement.

Step-by-Step TMV Maintenance Guide

A structured maintenance guide is crucial for ensuring the safe and efficient operation of TMVs. Proper procedures help maintain the desired heated water temperature, preventing thermal shock and scalding issues.

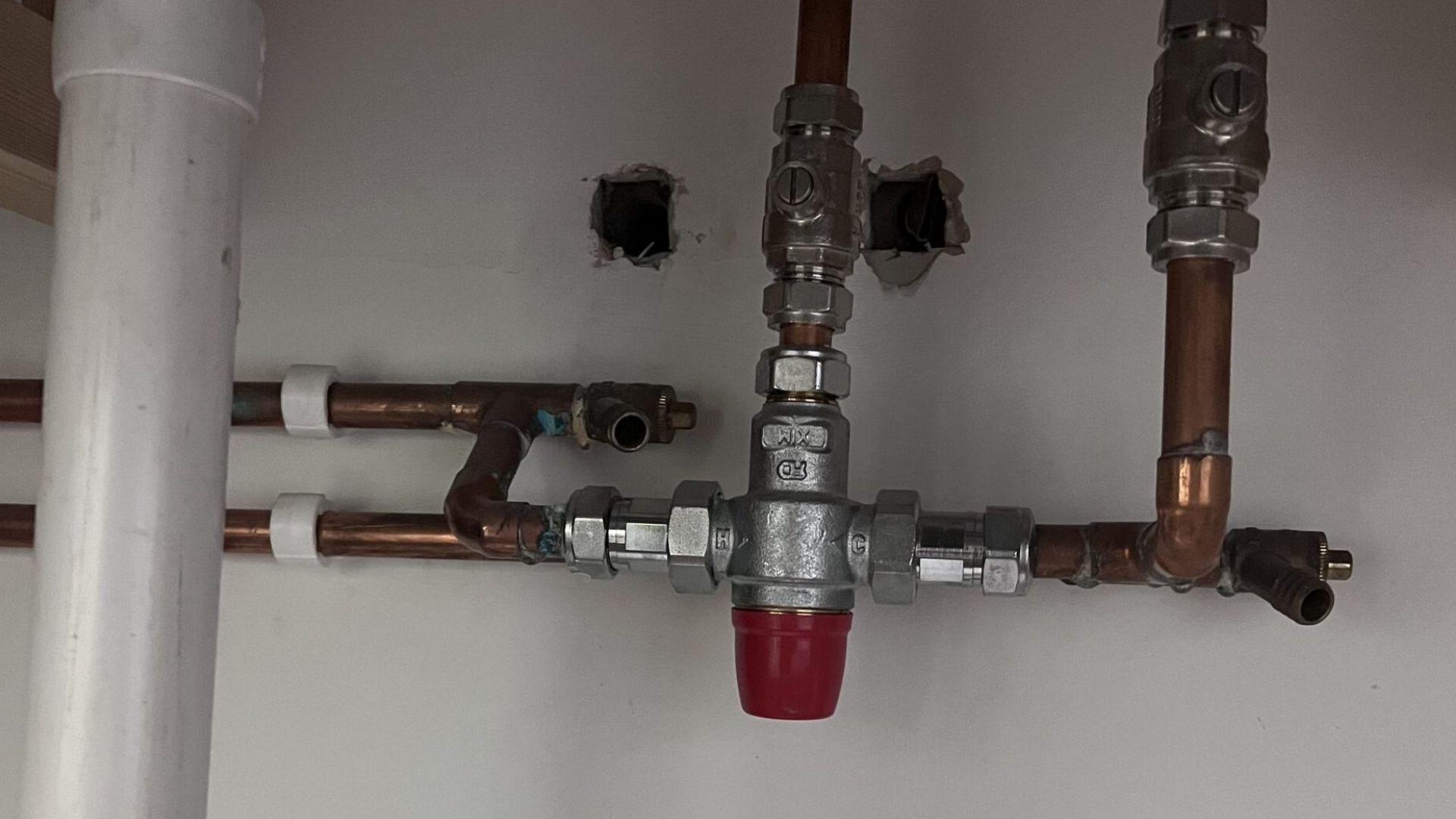

Inspection and Testing

How often you inspect and test TMVs depends on their specific setup and usage conditions. Generally, you should check them every six to twelve months to make sure they blend hot and cold water properly and keep the water temperature safe.

Thorough documentation of each inspection and testing session is vital. Record-keeping helps track the output temperature and identify when adjustments or repairs are necessary.

Cleaning and Disinfection

Proper techniques for cleaning and disinfecting TMVs are crucial for preventing contamination. Begin by shutting off the hot and cold water supply to the TMV. Use approved cleaning products and follow the manufacturer’s guidelines to ensure the TMV achieves optimal performance without damaging components.

Disinfection should be done carefully to maintain the safe water temperature outlet and prevent thermal shock. Always refer to the manufacturer’s instructions to use the correct methods and products.

Component Replacement

Periodic replacement of components like thermostatic elements and seals is necessary to maintain TMV efficiency. Over time, wear and tearcan affect the TMV’s ability to effectively blend hot and cold water. Using genuine parts from the manufacturer ensures compatibility and reliability. This helps maintain the desired heated water temperature and prevent scalding, ensuring long-term safety and performance.

Choosing the Right TMV for Your Facility

Selecting the suitable Thermostatic Mixing Valve (TMV) for your facility ensures optimal performance and safety. The correct choice depends on several factors, including water pressure, temperature requirements, and your facility’s needs. A well-chosen TMV enhances safety by preventing scalding and contributes to the overall efficiency of your plumbing system. Investing time in understanding your facility’s requirements will result in long-term benefits and peace of mind.

Regular maintenance of TMVs is essential to guarantee their effectiveness and compliance with safety standards. Routine checks and timely replacements of worn components can prevent potential issues and extend the life of the valves.

At Big Blue Plumbing, we provide expert TMV services to keep your systems running smoothly. Don’t hesitate to reach out if you have questions or require assistance with your TMV needs. Your safety is our top priority, and we are here to ensure your facility is equipped with reliable and efficient plumbing solutions. Contact Big Blue Plumbing today for comprehensive commercial TMV maintenance services.