Recent data from the Victorian Building Authority reveals that nearly 23% of industrial plumbing installations fail initial compliance inspections, resulting in project delays and substantial financial losses for businesses. In Queensland alone, non-compliant industrial plumbing systems led to over $15 million in remediation costs during 2023, highlighting the importance of understanding and adhering to Australian plumbing standards.

For facility managers and industrial property developers, dealing with plumbing compliance is not just about ticking boxes for regulations. It’s about keeping the workplace safe, running operations smoothly, and ensuring sustainability for the long haul. Failing to comply can lead to serious consequences, including steep fines, halted projects, and risks to both the environment and workplace safety.

This comprehensive guide explores the essential aspects of industrial plumbing standards and compliance in Australia, offering practical insights for professionals responsible for maintaining and implementing these crucial systems. Whether planning a new industrial facility or managing existing infrastructure, understanding these regulations is fundamental to your project’s success.

Overview of Industrial Plumbing in Australia

Industrial plumbing is crucial to Australia’s manufacturing and industrial sectors. It demands specialised knowledge and strict adherence to regulations that go well beyond everyday plumbing needs.

What is Industrial Plumbing?

Industrial plumbing encompasses complex systems that handle high-pressure, high-temperature, and often hazardous materials within manufacturing and processing environments. Unlike residential or commercial plumbing, which primarily deals with drinking water and sewage, industrial systems must manage chemicals, gases, waste products, and specialised materials essential to manufacturing processes.

Role in Large-scale Infrastructure

Industrial plumbing systems are critical in Australia’s factories, warehouses, and manufacturing facilities. They support vital operations through process piping, chemical transfer lines, industrial waste management, and specialised drainage systems.

These systems need to withstand extreme conditions, maintaining safety and efficiency in situations where failures could stop production or jeopardise worker safety. They often involve kilometres of piping, various pump stations, and advanced control mechanisms to ensure proper flow rates and pressure levels across massive industrial complexes.

Essential Plumbing Standards in Australia

For industrial facilities in Australia, plumbing standards are the cornerstone of safe and efficient operations. These regulations ensure consistency and safety across all industrial installations nationwide, protecting infrastructure investments and worker well-being.

National Regulatory Framework

ThePlumbing Code of Australia (PCA), as part of the National Construction Code (NCC), establishes the primary framework for industrial plumbing standards. The Australian Building Codes Board (ABCB) oversees these regulations, working alongside state-based authorities to maintain and enforce compliance requirements. Each state and territory maintains additional specific requirements through their local regulatory bodies, though all must meet or exceed national standards.

AS/NZS 3500 Series

The AS/NZS 3500 series forms the technical backbone of industrial plumbing requirements. This comprehensive set of standards covers:

- Water services (AS/NZS 3500.1)

- Sanitary plumbing and drainage (AS/NZS 3500.2)

- Stormwater drainage (AS/NZS 3500.3)

- Heated water services (AS/NZS 3500.4)

These standards are regularly reviewed and updated to keep up with technological advancements and the evolving needs of the industry.

Material and Installation Requirements

Australian standards mandate specific requirements for industrial plumbing installations:

- Pipe materials must meet pressure ratings suitable for industrial applications

- Joints and fittings must withstand chemical exposure and temperature variations

- Protective coatings must resist corrosion in aggressive industrial environments

- Support systems must accommodate thermal expansion and vibration

- Installation methods must follow prescribed procedures for different material types

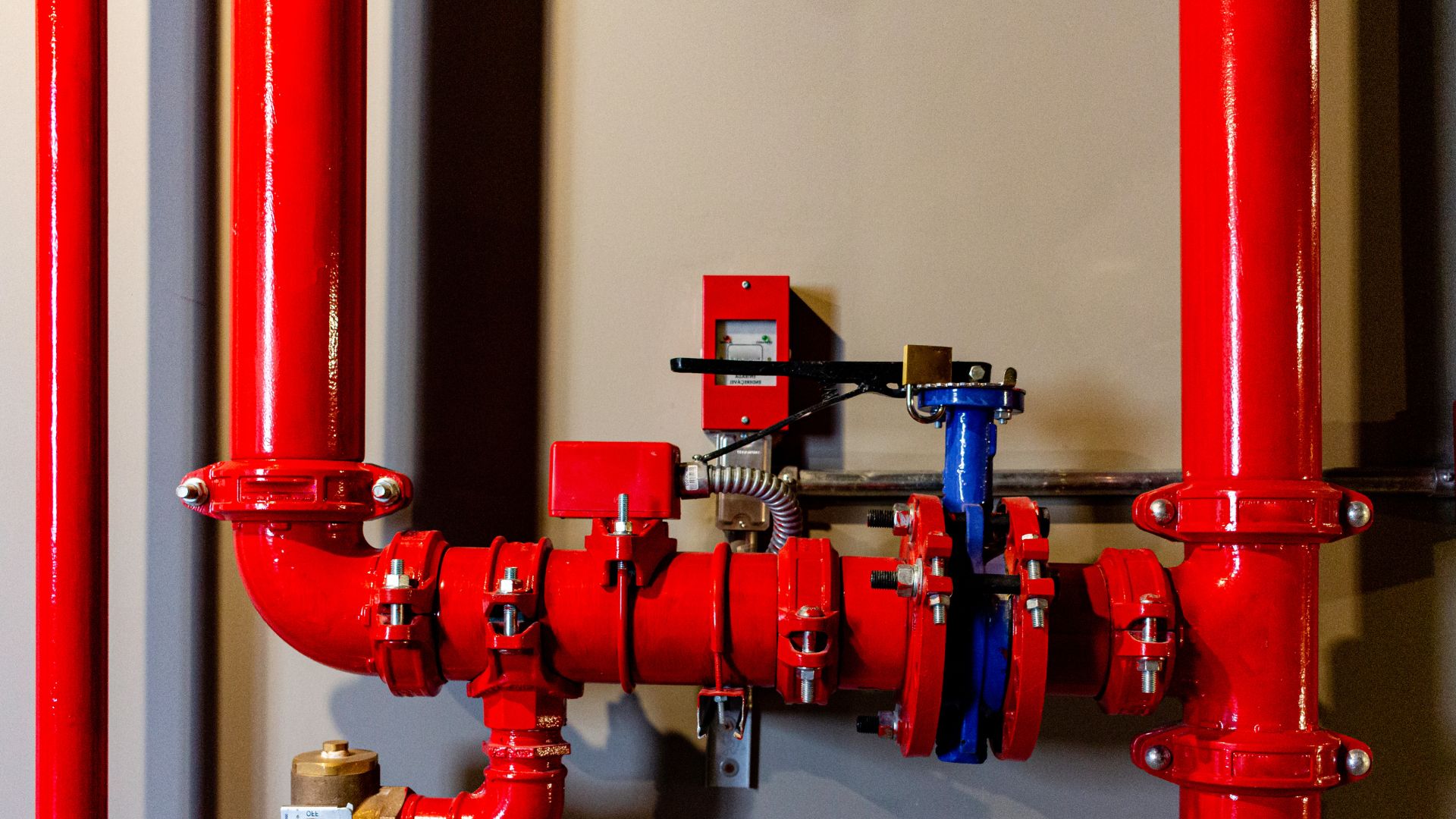

Safety and Prevention Measures

Essential safety requirements include:

- Backflow prevention devices for process water systems

- Emergency shutdown systems for hazardous material lines

- Pressure relief mechanisms for high-pressure installations

- Chemical-resistant drainage systems for waste management

- Proper ventilation for enclosed plumbing spaces

- Isolation valves at critical points for maintenance and emergency control

- Clear labelling and identification of all system components

These standards ensure industrial plumbing systems protect workers and the environment while maintaining operational efficiency and system longevity.

Compliance Requirements for Industrial Plumbing Projects

Industrial plumbing compliance isn’t just about rules; it’s about ensuring project viability, keeping the workplace safe, and protecting the environment across Australia’s industrial sector.

Understanding Industrial Plumbing Compliance

Compliance encompasses adherence to national standards, state regulations, and local council requirements. This multi-layered approach requires industrial projects to meet specific benchmarks at every stage, from initial design to final commissioning. Licensed practitioners must oversee all industrial plumbing work and maintain documentation throughout the project lifecycle.

Required Permits and Certificates

Industrial plumbing projects demand extensive documentation:

- Development approval from local councils

- Plumbing and drainage permits

- Trade waste agreements for industrial discharge

- Compliance certificates for completed works

- Backflow prevention device registration

- Water authority connection permits

- Gas installation certificates, where applicable

Inspection Requirements

Mandatory inspections occur at critical stages:

- Pre-construction design review

- Underground services installation

- Pressure testing of pipe systems

- Final inspection before commissioning

- Safety system verification

Common Compliance Issues

Industrial projects frequently encounter these challenges:

- Incorrect material selection for chemical processes

- Inadequate backflow prevention measures

- Non-compliant trade waste arrangements

- Insufficient access to maintenance

- Improper pressure ratings for system components

Impact of Non-compliance

The consequences of failing to meet standards include:

- Work stoppages and project delays

- Substantial financial penalties

- Mandatory system modifications

- Insurance coverage complications

- Production interruptions

- Environmental protection breaches

- Workplace health and safety violations

Common Challenges in Meeting Plumbing Compliance

For Australian businesses, meeting industrial plumbing compliance standards is challenging, especially when dealing with complex infrastructure and constantly changing regulations.

Infrastructure Limitations

Ageing industrial facilities often need to work on updated plumbing systems that fall short of current standards. Many factories built in the 1980s and 1990s face substantial upgrade requirements, while heritage-listed industrial buildings present unique compliance challenges due to structural limitations and historic preservation requirements.

Project Planning Deficiencies

Major compliance hurdles emerge from inadequate planning:

- Insufficient timeline allocation for inspections

- Underestimated budget for compliance measures

- Limited consideration of future expansion needs

- Poor coordination between trades and contractors

- Incomplete documentation of existing systems

Documentation and Record-Keeping Issues

Many companies often face issues like missing historical plumbing plans and incomplete maintenance records. They might also have outdated compliance certificates, inconsistent documentation of system modifications, and poor handover procedures during management changes.

Best Practices to Ensure Compliance

Maintaining plumbing compliance requires strategic planning and consistent implementation of proven practices across industrial facilities.

Professional Engagement

Success in industrial plumbing compliance starts with qualified expertise. Facilities must engage certified industrial plumbers for all installations and modifications. Compliance specialists should review project plans before implementation, while accredited inspectors must conduct regular audits. Strong relationships with local regulatory authorities prove invaluable, particularly when navigating complex requirements. System design requires collaboration with qualified engineers who understand compliance needs and operational demands.

Maintenance and Inspection Protocols

Regular maintenance forms the foundation of ongoing compliance. Critical components need weekly visual inspections to catch potential issues early. Backflow prevention devices demand monthly testing to ensure proper operation. Pressure relief systems require quarterly assessments to maintain safety standards. Drainage efficiency needs semi-annual review, while comprehensive system audits should occur annually to maintain complete compliance.

Documentation Management

Effective record-keeping supports long-term compliance efforts. Facilities should implement digital tracking for all maintenance activities and keep system diagrams current with any modifications. Compliance certificates and permits must remain organised and accessible. Incident reports and resolutions require detailed documentation, while worker training records need regular updates to demonstrate ongoing competency.

Quality Control Measures

Material selection and installation standards demand rigorous attention. Facilities must use only Australian Standard-approved materials throughout their systems. All components require verified pressure ratings that are appropriate for their application. Material compatibility checks need documentation before installation. Proper spare parts storage ensures maintenance quality, while testing equipment requires regular calibration.

Emergency Response Planning

Comprehensive emergency preparation prevents costly compliance breaches. Written procedures should outline response protocols for various scenarios. Current contact lists for relevant authorities must remain readily available. Backup systems need clear activation protocols, while maintenance teams should maintain quick-response capabilities. Staff training requires regular updates to ensure emergency readiness.

Role of Technology and Innovations in Industrial Plumbing Compliance

Modern technology transforms how industrial facilities monitor, maintain, and ensure plumbing compliance.

Smart Monitoring Systems

Digital sensors and automated monitoring equipment now provide real-time data on system performance. These tools track pressure levels, flow rates, and temperature variations, alerting maintenance teams to potential compliance issues before they become critical. Advanced leak detection systems help facilities maintain water quality standards and prevent environmental breaches.

Compliance Management Software

Integrated software solutions streamline compliance documentation and scheduling. These platforms automatically track inspection dates, maintenance requirements, and certification renewals. Digital record-keeping systems ensure accurate documentation of all plumbing modifications and repairs, creating comprehensive audit trails for regulatory inspections.

Future Innovations

Emerging technologies promise even greater control over compliance management. Artificial intelligence systems predict maintenance needs based on usage patterns, while virtual reality tools assist in system planning and worker training—remote monitoring allows experts to assess compliance issues without site visits, reducing response times and maintenance costs.

Ensuring Your Industrial Project Meets Australian Standards

Australia’s industrial plumbing standards, compliance, unwavering attention to detail, and professional expertise. The complexities of these requirements reflect their crucial role in protecting worker safety, environmental integrity, and operational efficiency. Facility managers and project developers must recognise that compliance isn’t merely a regulatory obligation—it’s an investment in operational sustainability and risk management.

Non-compliance consequences extend beyond immediate financial penalties, potentially resulting in production shutdowns, safety incidents, and long-term reputational damage. Proactive compliance management, through regular inspections, proper documentation, and engagement with qualified professionals, remains the most cost-effective approach to industrial plumbing maintenance.

Big Blue Plumbing has specialised knowledge and experience to navigate these complex requirements. Our team understands the unique challenges of industrial plumbing systems and maintains current expertise in Australian standards and regulations. For reliable industrial plumbing services that ensure compliance while maximising operational efficiency, contact Big Blue Plumbing. Our consultants stand ready to help your facility meet and exceed all regulatory requirements.